Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching, bearing in mind the high quality level and the most economical workflow even in the case of orders for large series.

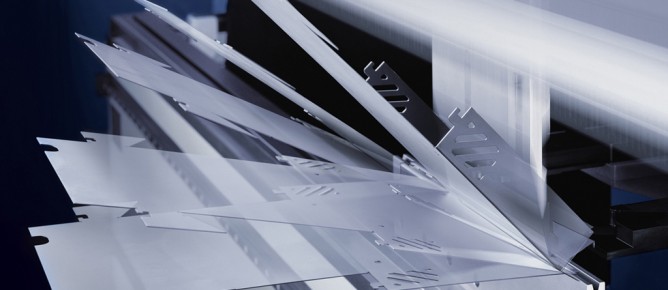

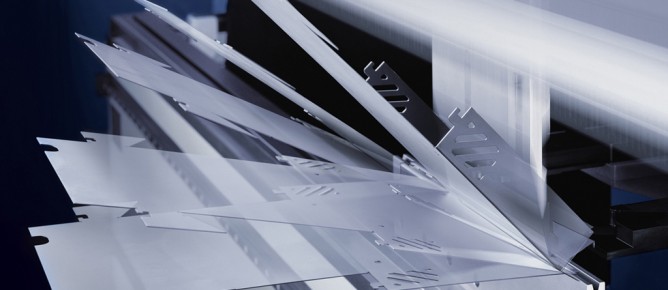

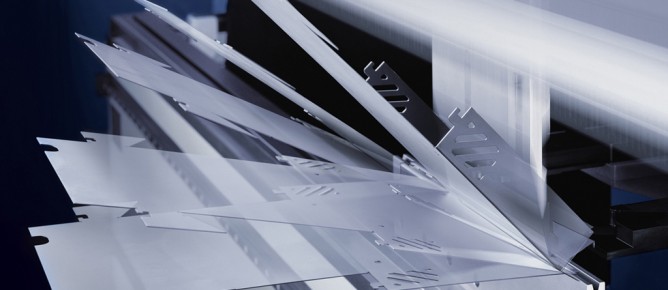

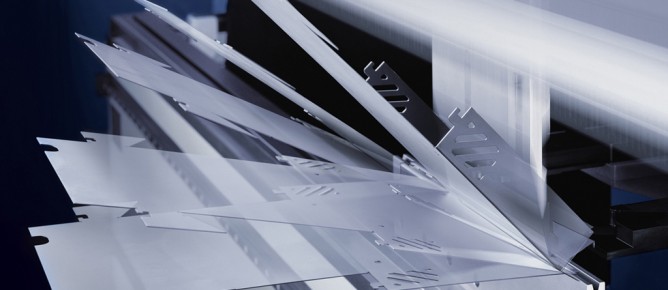

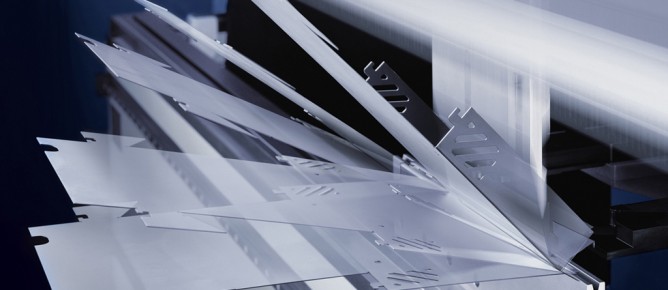

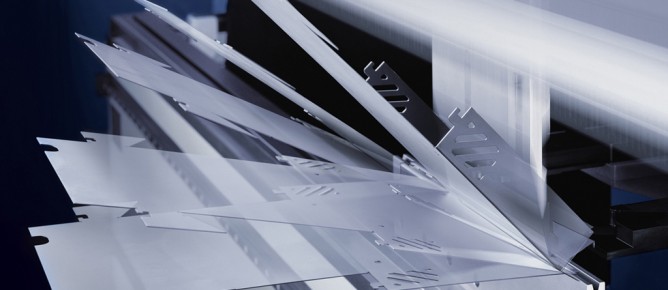

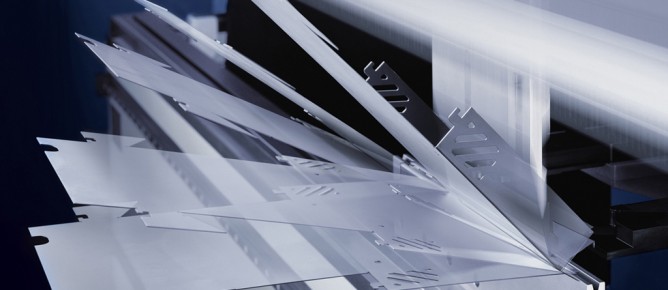

Characteristics of the punching technology:

- The rotation of every tool

- Production of large series with quick processing time

- Excellent quality workpieces without involving any heat

- Punching individual contours with one push, nibbling of intersections

- 3D punching with TRUMPF shaping tools

- Thread forming

- Paint resistant labelling with an embossing an marking tool

Our punching machines are capable of processing a sheet area as large as 3000 mm x 1500 mm, in the case of steel sheets with a thickness of 0.5 mm – 4 mm, 0.5 mm -3 mm in the case of stainless steel sheets, 0.5 mm – 5 mm in the case of aluminium and copper sheets, but it is also possible to process plastic sheets.

Our tooling is characterised by the fact we possess every standard size and several custom-made tools capable of carrying out several special operations and to implement the shaping procedures provided by the technology.

Manufacturing processes are supported by the ToP100 software developed by the TRUMPF company, 3D-planning takes place with the Solid Edge planning software, while professional know-how is provided by our experienced, creative technical specialists.

-

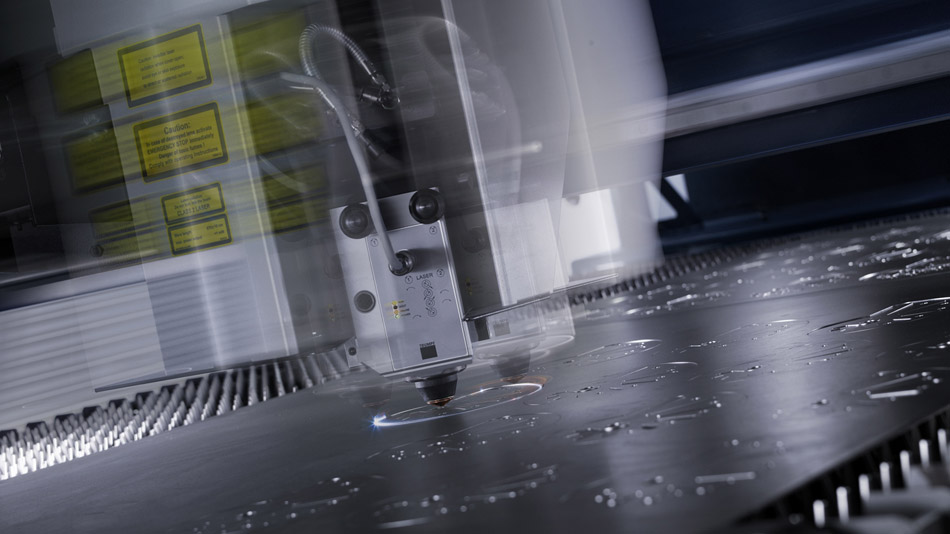

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant.

Types of cutting in the case of laser cutting:

- Laser cutting with oxygen is used in the case of normal steels.

- In the case of laser cutting with nitrogen, high-pressure nitrogen is used with stainless steels and aluminium and in the case of component parts to be treated with electrostatic painting, as this process facilitates the adsorption of paint on the cut surface.

Advantages of laser cutting as opposed to other machining types:

- Burr-free cut surface

- Efficient, high level of elaborateness, intricate figures

- Fast and flexible technology

- No need for tools or a change of tools

- Besides cutting it can also be used for marking and engraving

- Small heat affected zone

Laser cutting takes place with a 4000 W Trumatic L3030 device with a panel size of 1500 mm x 3000 mm and a 4000 W Trumatic L2530 with a panel size of 1250 mm x 2500 mm.

Our machines are programmed with the ToPs100 software developed by the TRUMPF company, which guarantees effective and precise work.

.

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

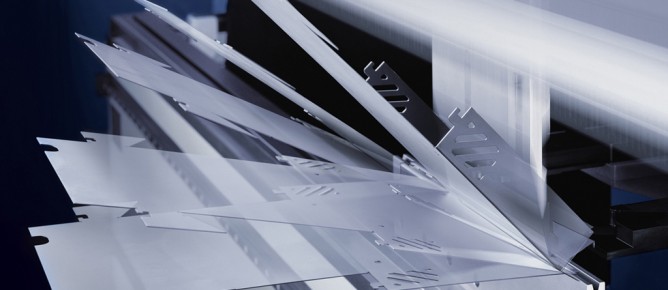

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. Our tooling is characterised by the fact that besides standard prisms and blades we also possess a number of special tools due to our work experience covering several decades and the continuous challenges. The blade- and prism-kits bought during the years and manufactured for customised works enable us to state, that practically nothing is impossible for us in the field of bending.

Our edge bending activities are:

1. High precision CNC edge bending

2. Reverse mounting

3. Bending of bracings

4. Radius bending

Our bending ranges:

- Material thickness: 0.5 mm – as a function of bending length it can be as long as 15 mm

- Maximal bending length: 4000 mm

Our edge blending machines:

- AMADA IT 1250/20 t – 4 axes CNC edge bending machine

- AMADA APX 2000/50 t – 7 axes CNC edge bending machine

- AMADA HFP 3000/100 t– 7 axes CNC edge bending machine

- AMADA HFE 4000/220 t – 7 axes CNC edge bending machine

- GUIFIL SC 3000/110 t – 8 axes CNC edge bending machine

- DEZ 2500 /20 t – 4 axes CNC edge bending machine

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

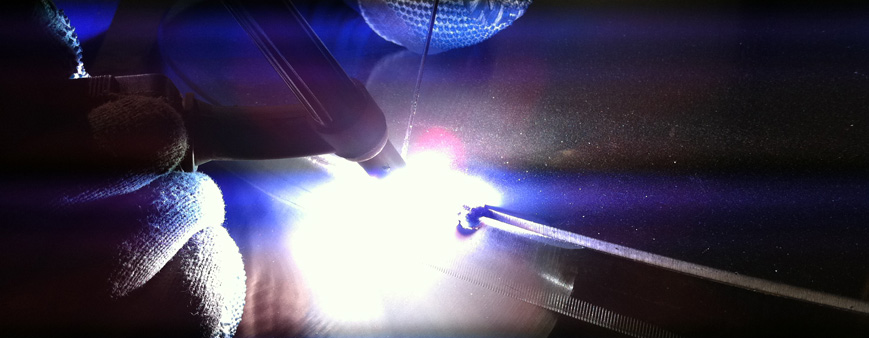

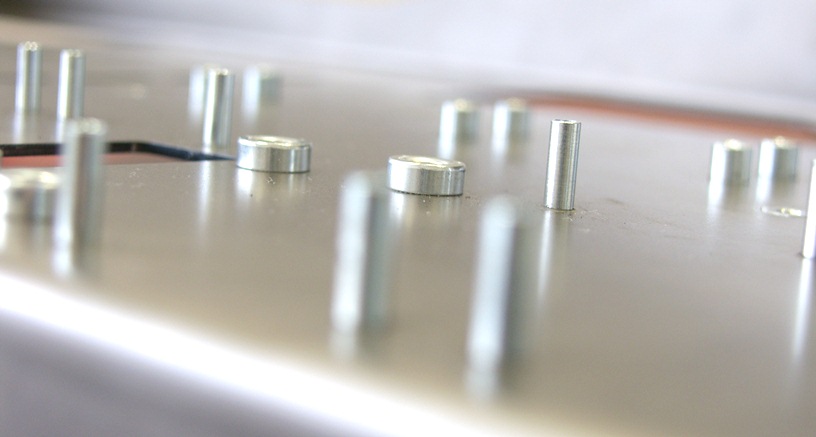

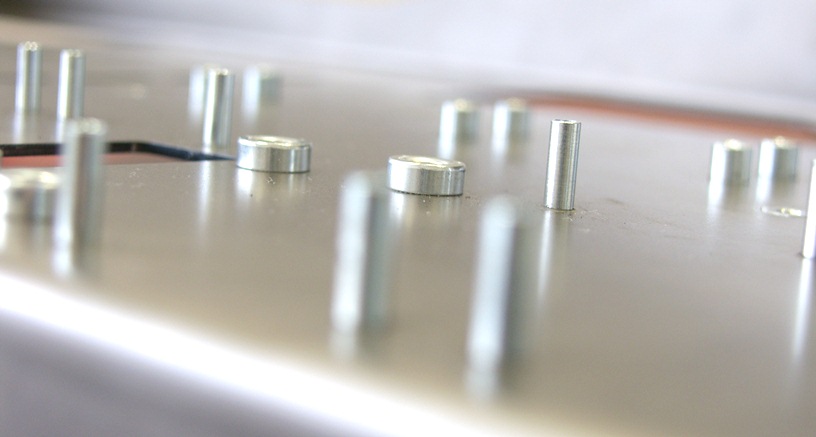

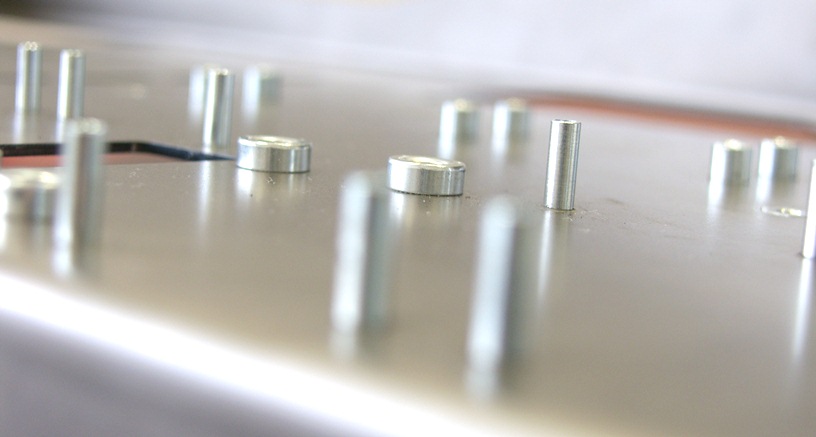

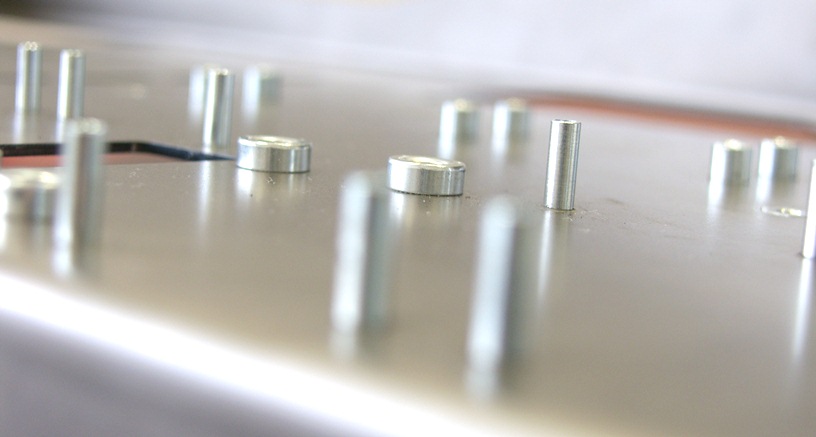

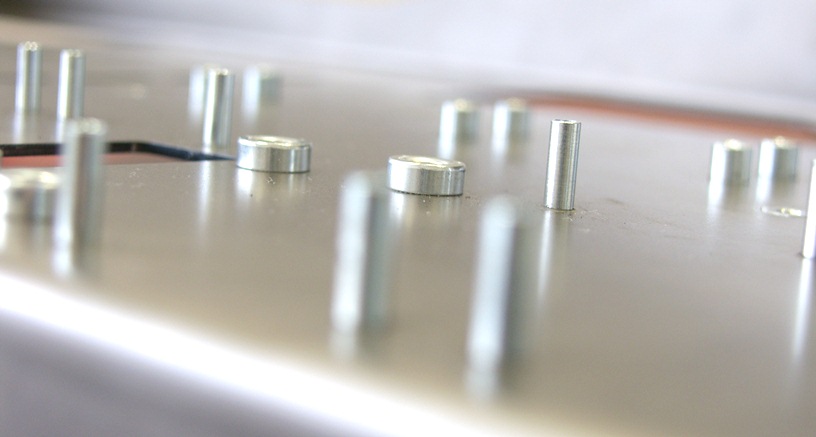

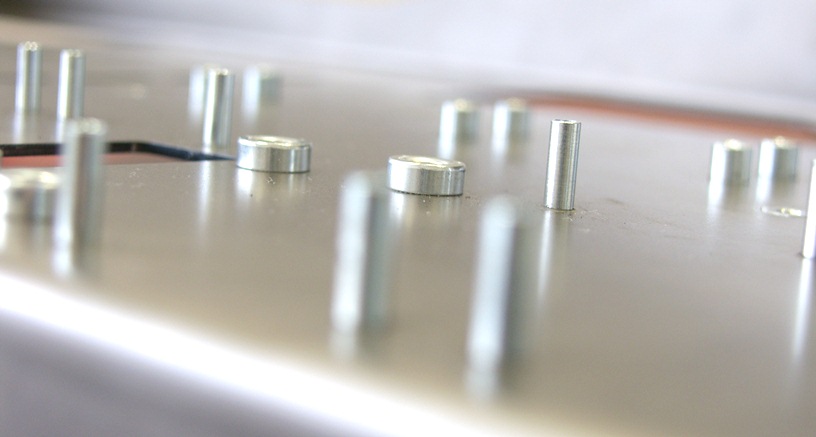

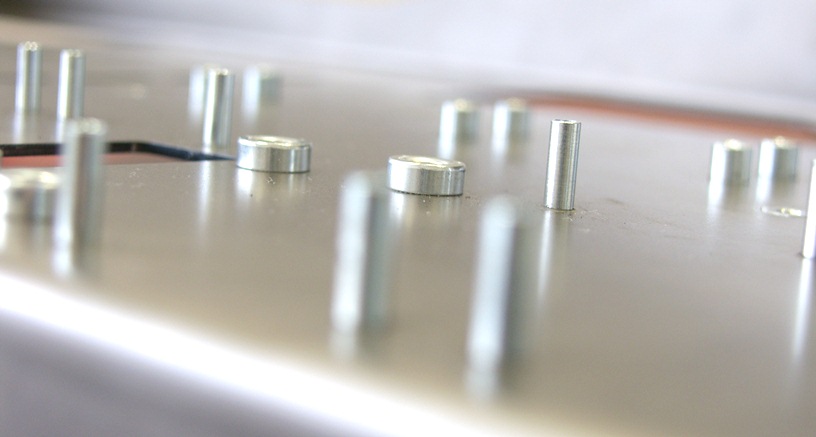

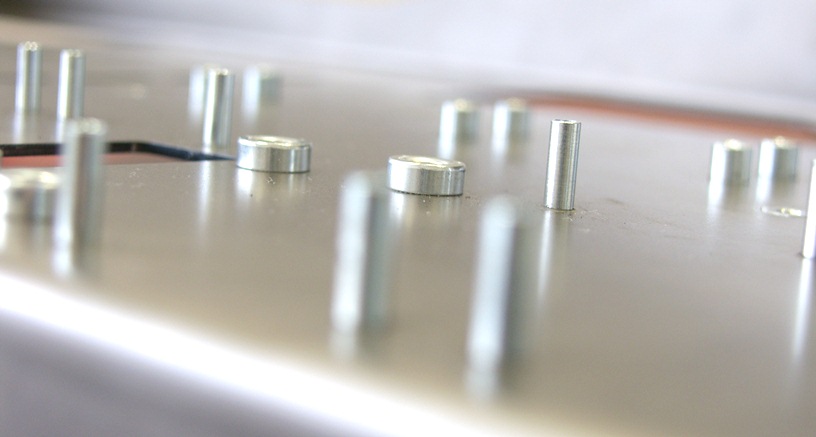

GROUTING OF FASTENERS, STUD WELDING

Several areas of the modern industry extremely thin and light component parts, such at sheet metals, printed circuit boards or plastic workpieces are used. These have to be fastened securely and permanently, together with ensuring high anti-unscrewing and –unplugging values.

The PEM® groutable fasteners are widely used from the field of electronics and the automotive industry to the production of machines and devices, airplanes and spaceships. These fasteners do provide permanent and safe fastening in each case. The PEM® groutable fasteners provide high performance, are easy to install and save time and expenses.

ADVANTAGES

- Extreme load capacity even in the case of smaller and thinner sheet metals

- The special preparation of the mounting holes is not required

- Repeated threading is not necessary

- It is ideal even for coated surfaces

- High placement precision

- Time- and cost-economical

With our PEMSERTER® Series 4 press the following fasteners can be grouted on a high quality level:

Machinable materials:

- Carbon-steels

- Corrosion- and acid-resistant materials

- Aluminium materials

- Plastics

- The maximal distance of the fastener from the edge of the plain component part: 450 mm

- The thickness of the thinnest machinable sheet: 0.8 mm

- In the case of groutable studs: in sizes M2.5-M6, up to a sheet metal thickness of 35 mm, L=6-8-10-12-15

- In the case of groutable spacers: in sizes M3-M5, up to a sheet metal thickness of L=3-25 mm

In the case of groutable nuts: in sizes M2-M10

FASTENER STUD WELDING

The SOYER® PS-9 stud welding pistol with the related SOYER® BMS-9 power supply represents the most up-to-date stud welding technology. As opposed to the traditional bolt staples, in the case of the new type of collet it is not necessary to set loose studs one by one and to adjust the bolt staple to the studs of different length (6-40 mm). This is the very first time it becomes possible for the operator to recognise all important operating conditions at once with the help of the LED on the pistol displaying the colours of a traffic light. This hugely facilitates the work of the operator and significantly increases the quality of weldings.

ADVANTAGES

- Mobility, can be applied even in the case of large component parts

- No mounting hole needed

- High placement precision

- No burn mark or deformation appears on the backside of even the thinnest welding surfaces not even if the backside is covered with plastic, foil or has received electrolytic surface treatment

- No ceramic ring or shielding gas is required

With our SOYER® BMS-9 stud welding machine the following fasteners can be welded in on a high quality level:

Machinable materials:

- Carbon-steels

- Corrosion- and acid-resistant materials

- Aluminium materials

- Copper materials

- The thickness of the thinnest machinable sheet: 1 mm

- In the case of groutable studs: studs with sizes M3-M8, and Ø 2-8 mm and a length of 6-35 mm

- Positioning preciseness: ±0.5 mm

Welding speed: Max. 20 studs/minute, depending on the size

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

Our enterprise has committed itself to solve the requirements arising on behalf of the Customers and becoming increasingly complex in an effective way. For this very purpose it is essential to have a well-equipped locksmith’s workshop with a properly trained staff, where, besides the different structural elements also machine covers, electrical cabinets and other high quality sheet metal products can be produced, even from stainless steel materials.

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work:

- Welding machines for the TIG / MIG / MAG technologies

- Spot welding machine

- Stud welding machine – Soyer

- Pulling tools – Böllhoff

- Presses – PEM

- Material removing, abrasive machines

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

Our engineer colleagues are ready to be at your disposal with several years of planning experience.

Our Solid Edge planning software supports production, helps with preparing the 3D models, the settings and shop drawings being indispensable for sheet metal production.

With our TrueTops software the most optimal allocations and the shortest conversion periods possible are technologised.

Supported file formats:

- .dxf

- .dwg

- .iges

- .step

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. It forms anti-corrosive coating, which with the proper surface preparation may prevent the surface from corrosion for five, ten, even fifteen years. It resists UV-radiation and weather conditions well.

In accordance with the stipulations of the technology, paint in powder form is applied onto different metal surfaces with spray guns. The powder adsorbs to the surface due to the electric charge, which powder is then burned onto the surface in a furnace with a temperature of 180-220 °C. After burning in, once the product cools down, it can at once be packaged and even transported.

Our powder painting shop has a burning furnace with a length of 7500 mm and a width of 1600 x 1100 mm, to which three spray booths are attached that make painting in several colours at the same time possible. Fast switching from different colours and undertaking orders with a short deadline mean absolutely no problem at all. Large series and individual orders are dealt with alike.

Powder coating is carried out with Gema and Wagner spray guns.

The surface is prepared according to the requirements with degreasing, phosphate coating or abrasive blasting. Degreasing is carried out with a wash-tub and high-pressure spraying technology, in accordance with the stipulations of the related standards.

The colour palette is endless; painting any of the colours on the RAL-card is possible, while the custom-made extra colours of several production companies are also at our disposal.

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface. It may be utilised in a wide range of individual surface treatment procedures. Preparing the surfaces in such a way significantly affects the durability of further surface treatment procedures.

Our abrasive blasting device is operated manually with a high performance in a 6m x 6m x 4.5m cabin, which enables the precise, high quality surface cleaning of profiled workpieces, and the cleaning of large, bulky workpieces, as well.

The device can be used in all areas where B Sa 3 or C Sa 2 surface cleanliness level is a must, in accordance with the MSZ ISO 8501–1 standard, or achieving a certain level of surface roughness is a technical requirement.

Abrasive blasting is carried out with S-170 sphere-shaped steel shot. The abrasive material is applied on the surface to be cleaned with the energy of compressed air.

Fields of application concerning the different materials:

Steel:

- descaling

- corrosion removal

- weld seam testing

- preparation of painting, galvanisation

- paint removal

Stainless steel:

- removal of welding traces

- establishing the final, homogeneous surface

- matting, removal of surface scratches

Non-ferrous metals:

- establishing the final, homogeneous surfaces

- preparation of painting, galvanisation and anodising

Further applications of the abrasive blasting technology:

- matting

- roughening

- smoothing

- ensuring adhesion

- removal of different surface pollutions, paint-, acid- and oil-derivatives

-

Laser cutting

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant. -

Punching

Our company provides reliable solutions in order to meet high level customer requirements in the field of perforation, offcutting and punching. -

Edge bending

Our CNC-controlled bending machines comply with the most diverse bending requirements arising in the field of sheet metal working. -

Grouting of fasteners, stud welding

Several areas of the modern industry extremely thin and light component parts are used. -

Metal works

Our department possesses any and all equipment, tools and devices requires for precise, effective quality work. -

3D planning

Our Solid Edge planning software supports production, helps with preparing the 3D models. -

Powder coating

Electrostatic powder coating is one of the most up-to-date and environmentally friendly technologies of surface treatment. -

Abrasive blasting

Abrasive blasting is a surface treatment procedure. It ensures a homogeneous, pollution-, scale- and corrosion-free protective surface.

Linardics Kft.

Linardics Kft.