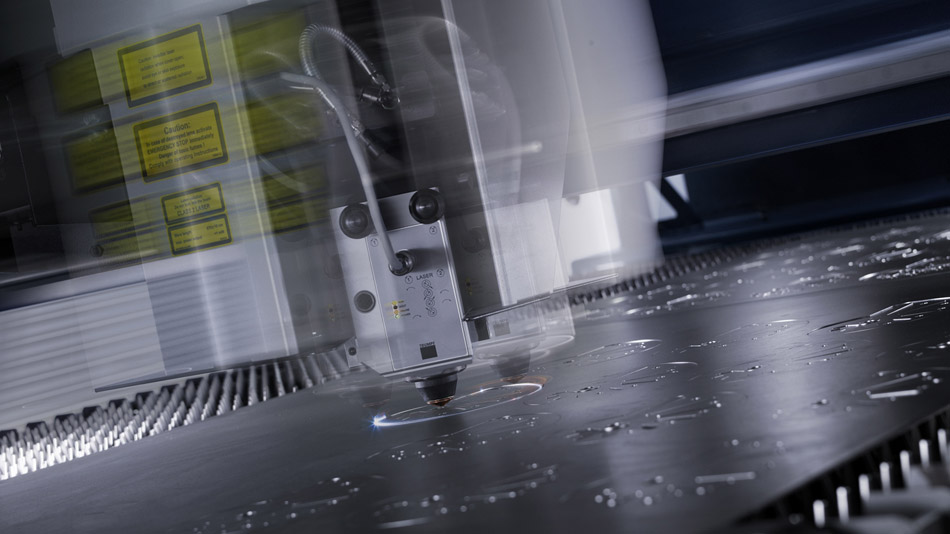

Besides punching, laser cutting is one of the primary cutting technologies of our sheet metal plant.

Types of cutting in the case of laser cutting:

- Laser cutting with oxygen is used in the case of normal steels.

- In the case of laser cutting with nitrogen, high-pressure nitrogen is used with stainless steels and aluminium and in the case of component parts to be treated with electrostatic painting, as this process facilitates the adsorption of paint on the cut surface.

Advantages of laser cutting as opposed to other machining types:

- Burr-free cut surface

- Efficient, high level of elaborateness, intricate figures

- Fast and flexible technology

- No need for tools or a change of tools

- Besides cutting it can also be used for marking and engraving

- Small heat affected zone

Laser cutting takes place with a 4000 W Trumatic L3030 device with a panel size of 1500 mm x 3000 mm and a 4000 W Trumatic L2530 with a panel size of 1250 mm x 2500 mm.

Our machines are programmed with the ToPs100 software developed by the TRUMPF company, which guarantees effective and precise work.

.

Linardics Kft.

Linardics Kft.